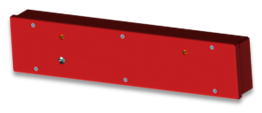

Ink Protected NCR Recycler Casette

An easy to install, multi-vendor ink staining solution for the highest ATM security level

The Villiger ATM ink security solution features the highest security level as well as being simple to locally install and easy to maintain. The ink modules and control units adapt to every brand of ATM and become integrated inside the existing cassettes. The system can integrate a complete end-to-end solution, in combination with the ATM Trolley.

Protection

- Cash is protected through indelible ink

- Full protection from unauthorized opening – sabotage, break-in, tilting, heating, etc.

- The system will activate through one of the following incidents:

- Cassette movement

- Open cover

- Shock detection

- Breaking-in, ramming, heating or any other attempt of unauthorized opening

Advantages

- Minimal changes to the original cassette

- Simple to operate – no need to use keys

- High savings on operational and insurance costs

- Ink replacement between 5 to 8 years

- Battery replacement every 5 to 8 years

- Flexibility – can integrate a complete end-to-end solution

- Compatible with other Villiger solutions like the Trolley System, Locker System and the Cash Center Units

Do You Like a Consultation?

Best Return On Investment (ROI)

By looking for total cost of ownership. Pioneering for more than 30 years with ink staining for cash protection.

Ink Staining Security

Valuables are protected during vehicle transport and on pavement through indelible ink.

Total 360° Security

Full protection from unauthorized opening – sabotage, break-in, cutting, drilling, heating, etc. on the ATM.

Adaptive Security

Flexibility – the product can adapt to any process with quick settings. Time and security can be scaled to your needs.

Low Maintenance Cost

Long service intervals where customers technicians can be trained to perform local service within minutes.

Trace & Tracking

Every product has its internal trace to track its process. The log history provides insight to every movement the product has made.

Pharma

Pharma Railway

Railway Maritime

Maritime Aerial

Aerial Postal

Postal Luxury

Luxury Value

Value