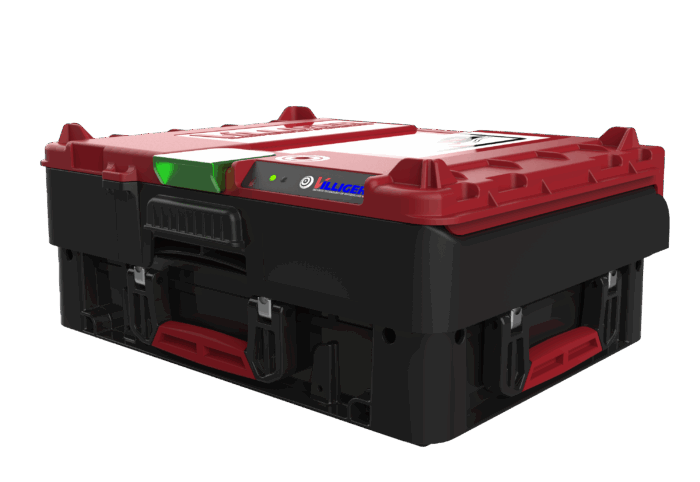

Coin Logistic System

Cost Efficient – Faster – Flexible

An easy-to-install Logistic System for the efficient use of coin boxes in armored, partial armored and soft-skin vehicles.

The efficient use of space: Standard boxes allow for optimal use of available space during transportation. They are designed to fit together and stack easily, minimizing wasted space in vehicles, or cash centers. This efficiency can lead to cost savings by reducing the number of shipments required and maximizing the amount of goods that can be transported at once.

Protection

- Compatibility with automation: Standardized boxes are compatible with automated systems and machinery used in modern logistics operations. They can be easily integrated into conveyor systems, robotic picking systems, and automated storage and retrieval systems, enhancing efficiency and speed in warehouses and distribution centers.

- Improved inventory management: Using standard boxes makes inventory management more organized and efficient. With uniform box sizes, it becomes easier to count and track the number of units in a shipment, calculate storage capacity, and manage stock levels. Standardized boxes also simplify labeling, barcoding, and scanning processes, enabling accurate tracking and tracing of goods.

- Overall, the use of standard boxes in logistics provides operational advantages, cost savings, improved product protection, and streamlined processes throughout the supply chain.

Advantages

Using a rack on wheels, also known as a mobile rack or rolling rack, offers several benefits in various settings:

- Efficient use of space: Mobile racks maximize the use of available space by enabling compact storage and easy access. They can be designed to have multiple shelves or levels, allowing for vertical storage and efficient organization of boxes. This vertical storage capability helps to optimize floor space, especially in vehicles where space is limited and boxes can be accessed from the front (inside the vehicle) and from the back (outside the vehicle).

- Time and labor savings: The mobility of racks reduces the time and effort required for manual handling tasks. Instead of moving boxes individually or carrying heavy loads across a facility, workers can quickly load or unload multiple boxes in a mobile rack and transport them in one trip. This saves time and increases productivity, allowing employees to focus on more value-added activities.

- Flexibility and mobility: A mobile rack allows for easy movement and repositioning of boxes within a facility. It eliminates the need for heavy lifting or manual transportation, as the rack can be easily rolled or pushed to the desired location. This flexibility enables efficient space utilization and adaptability to changing operational needs.

- Versatility and adaptability: Mobile racks come in various sizes, configurations, and designs, making them suitable for a wide range of applications. They can be used in cash centers, process facilities, and vehicles. Additionally, mobile racks can be customized or equipped with accessories such as dividers, bins, or trays to accommodate different types of boxes.

Do You Like a Consultation?

Best Return On Investment (ROI)

By looking for total cost of ownership. Pioneering for more than 30 years with ink staining for cash protection.

Ink Staining Security

Valuables are protected during vehicle transport and on pavement through indelible ink.

Total 360° Security

Full protection from unauthorized opening – sabotage, break-in, cutting, drilling, heating, etc. on the ATM.

Adaptive Security

Flexibility – the product can adapt to any process with quick settings. Time and security can be scaled to your needs.

Low Maintenance Cost

Long service intervals where customers technicians can be trained to perform local service within minutes.

Trace & Tracking

Every product has its internal trace to track its process. The log history provides insight to every movement the product has made.

Pharma

Pharma Railway

Railway Maritime

Maritime Aerial

Aerial Postal

Postal Luxury

Luxury Value

Value